In the textile and apparel industry, fabric is one of the most fundamental and critical aspects. A fabric’s appearance, feel, and performance are largely determined by its weaving method. Understanding different weaving methods not only helps designers make more informed material selection decisions but also allows customers to more clearly understand the fabric’s characteristics and application scenarios. This article will introduce the three main categories of fabrics from the perspective of weaving methods: woven fabric, knitted fabric, and nonwoven fabric.

1. Woven Fabrics

Definition

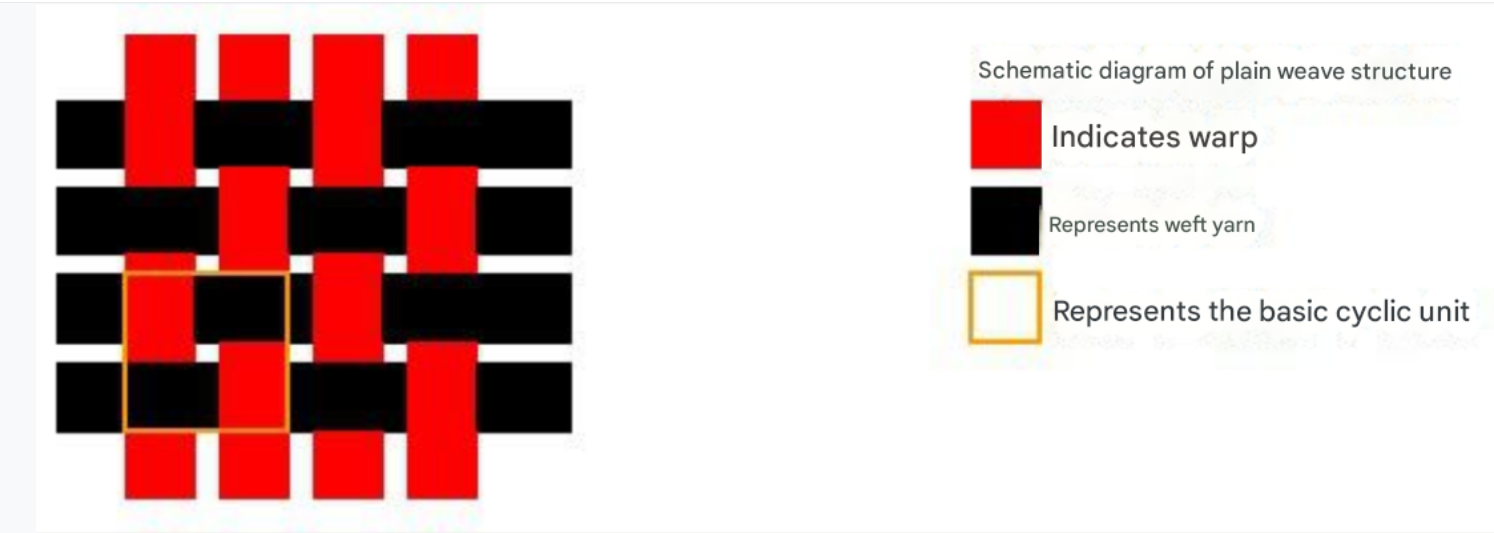

Woven fabrics are made by interweaving two sets of perpendicular yarns (warp and weft).

Features of Woven Fabrics

Strong stability: Tight structure, less prone to loosening or deformation.

Durability: High strength, wear resistance, and long life.

Weak elasticity: Limited stretch compared to knitted fabrics.

Common Types of Woven Fabrics

Poplin (Canvas): A weave made by interweaving warp and weft yarns in an even pattern, one above and one below.

Plain Weave: Cotton fabrics like plain cloth, poplin; Wool fabrics like valance, paisley, and tweed; Silk fabrics such as georgette, taffeta, and crepe de chine.

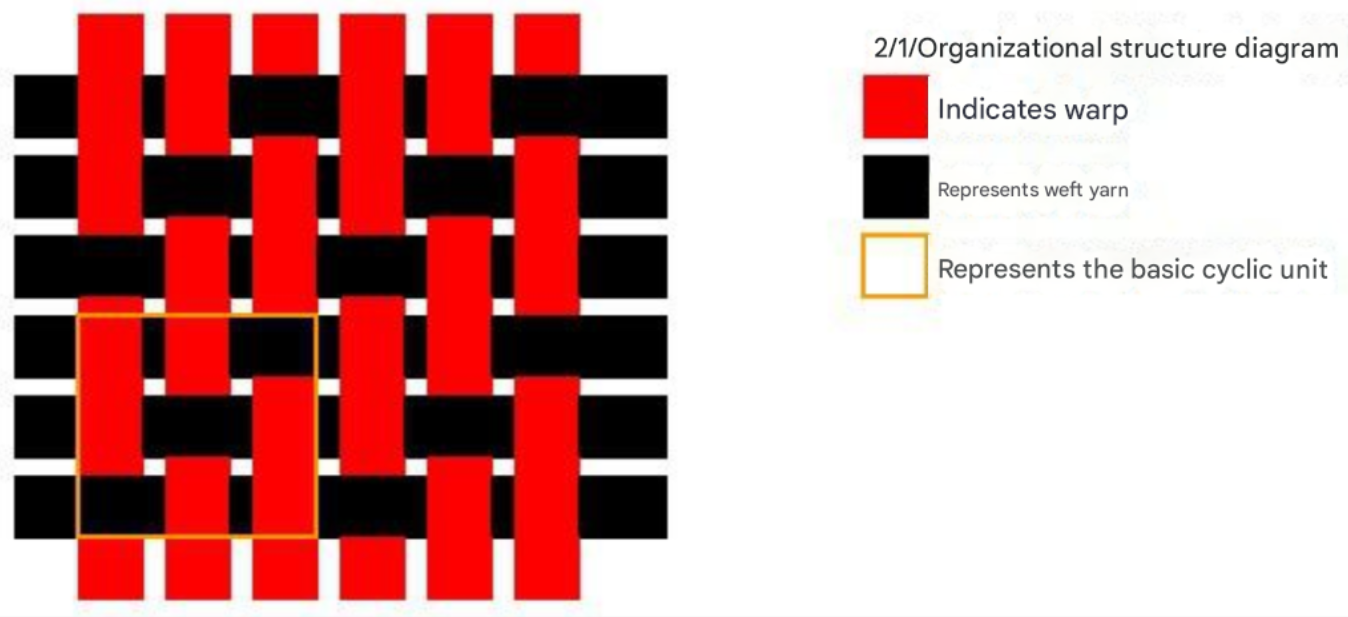

Twill Fabrics: Including denim and gabardine, characterized by diagonal lines in the weave.

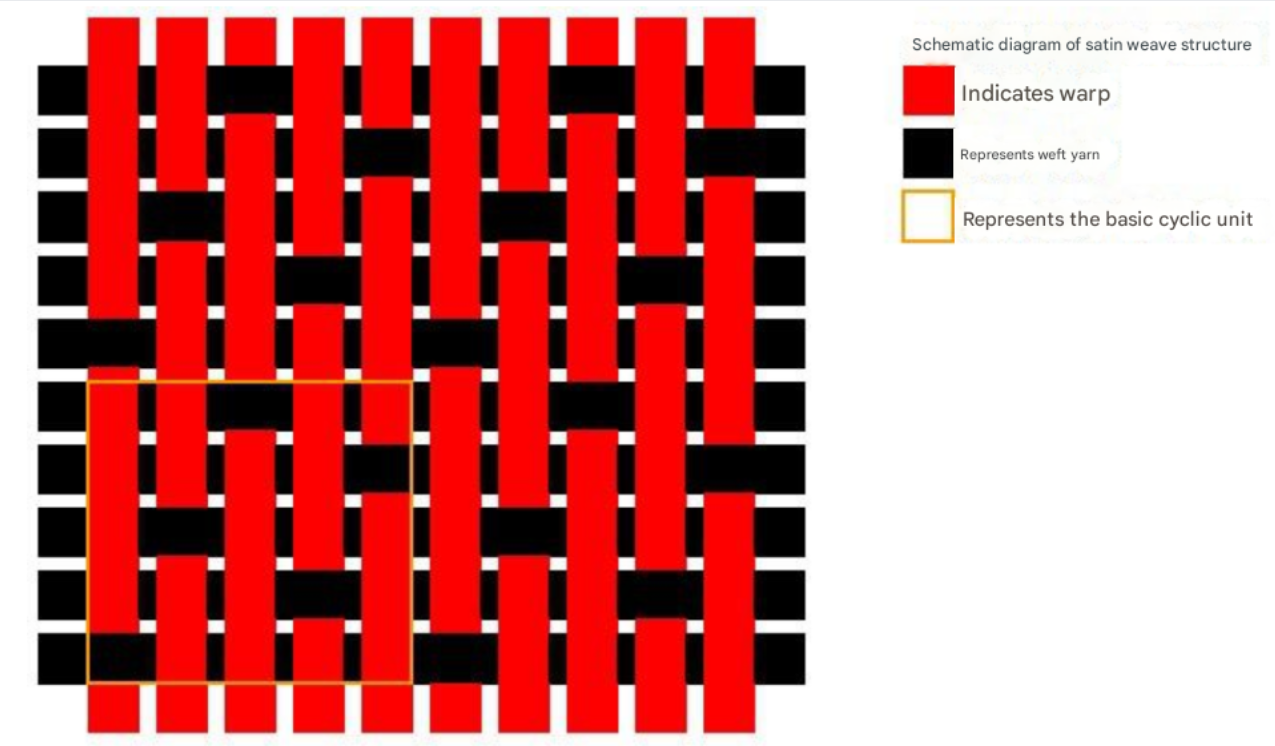

Satin: Fabrics with long floats in either the warp or weft direction, such as silk satin, horizontal satin, and vertical satin.

Applications of Woven Fabrics:

Shirts, suits, jeans, jackets, and home textiles.

2. Knitted Fabrics

Definition

Knitted fabrics are made by forming one or more yarns into loops and then interlacing them.

Features of Knitted Fabrics

Excellent elasticity: Suitable for physical activity and comfortable to wear.

High breathability: The fabric has a loose structure, making it suitable for summer or sportswear.

Easily deformed: If not properly cared for, the edges may curl or snag.

Common Types of Knitted Fabrics

Weft Knitting: Examples include single jersey, rib, and French terry.

Warp Knitting: Examples include mesh, warp velvet, and tricot.

Applications of Knitted Fabrics:

T-shirts, sportswear, sweaters, underwear, and swimwear.

3. Nonwoven Fabrics

Definition

Nonwoven fabrics bypass traditional spinning and weaving processes. Instead, fibers are bonded together mechanically, thermally, or chemically.

Features of Nonwoven Fabrics

High production efficiency: Simple process, low cost.

High functionality: Waterproof, filtration, or antibacterial properties can be added as needed.

Relatively limited durability: Low strength, mostly used in disposable or functional products.

Common Categories of Nonwoven Fabrics

Spunbond Nonwovens: Widely used in packaging, home furnishings, and medical applications.

Meltblown Fabric: Offers excellent filtration properties, commonly used in masks.

Needle Punched Fabric: Mechanically reinforced, commonly used in industrial applications.

Applications of Nonwoven Fabrics:

Masks, eco-friendly bags, medical supplies, filter materials, and disposable items.

IV. Summary and Application Recommendations

Fabrics produced using different weaving methods have their own unique characteristics:

Woven Fabrics: Stable and wear-resistant, suitable for both formal and durable clothing.

Knitted Fabrics: Soft and comfortable, suitable for sportswear, casual wear, and intimate apparel.

Nonwoven Fabrics: Highly functional, widely used in medical, industrial, and daily necessities applications.

In clothing design and production, the rational choice of weaving methods and fabrics can not only improve the quality and comfort of products but also create a more competitive product portfolio for the brand.